盡管在中國許多公司使用臭氧對潔凈室進(jìn)行消毒,許多業(yè)內(nèi)人士對其消毒效果也將信將疑。本文匯總了國內(nèi)外不同法規(guī)/指南對臭氧消毒濃度及其條件的要求,供大家參考:

GB 28232-2020《臭氧消毒器衛(wèi)生要求》:

空氣消毒臭氧濃度:5 mg/m3~30 mg/m3 ,相對濕度≥70%,作用是將為30~120min。

物體表面消毒:臭氧濃度應(yīng)≥60 mg/m3 ,相對濕度≥70%,作用時間60 min~ 120 min。

用臭氧水對物體表面消毒時:水中臭氧濃度應(yīng)≥10 mg/L,作用時間≥60 min。

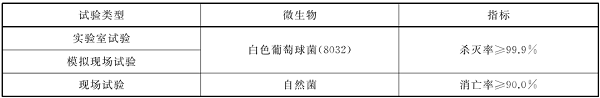

消毒效果應(yīng)達(dá)到以下標(biāo)準(zhǔn):

空氣消毒

臭氧消毒器用于空氣消毒時,應(yīng)符合以下要求:

消毒空氣時殺滅微生物指標(biāo)

水消毒

臭氧消毒器用于水消毒時,應(yīng)符合以下標(biāo)準(zhǔn):

消毒水時殺滅微生物指標(biāo)

醫(yī)療器械和用品消毒

臭氧消毒器用于醫(yī)療器械和用品消毒時,應(yīng)符合以下標(biāo)準(zhǔn):

消毒醫(yī)療器械和用品時殺滅微生物指標(biāo)

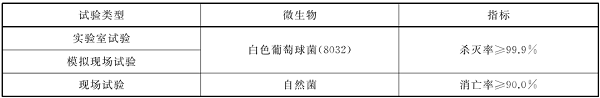

物體表面消毒

臭氧消毒器用于物體消毒時,應(yīng)符合以下標(biāo)準(zhǔn):

消毒物體表面時殺滅微生物指標(biāo)

驗證指南

消毒時關(guān)閉相應(yīng)的新風(fēng)進(jìn)口和回風(fēng)排放閥門,使整個被消毒的潔凈區(qū)空氣通過凈化系統(tǒng)風(fēng)管形成循環(huán),臭氧發(fā)生器即開始工作。如每日做空氣滅菌,一般可開機(jī) 1~1.5h;如每周以臭氧代替化學(xué)試劑熏蒸對物體表面、墻壁、地面及設(shè)備滅菌,一般可開機(jī) 2~2.5h。

對空氣中浮游菌,臭氧滅菌濃度為(2~4)×10^-6(2~4ppm);對物體表面的沉降菌,為(10~15)×10^-6(10~15ppm)

設(shè)計、應(yīng)用臭氧滅菌 60min 達(dá)到相對濃度后,繼續(xù)保持一段時間 (1~1.5h), 即可達(dá)到對機(jī)器設(shè)備和建筑物體表面沉降菌殺滅的目的。

PDA TR 70 無菌生產(chǎn)設(shè)施的清潔消毒程序原理

The use of Ozone Gas is another alternative for gassing small or large scale operations. Ozone is made by adding high voltage to oxygen. The system uses a high concentration of ozone gas that bintegrates a gas generator to emit the Ozone to the area to be decontaminated. Normally the design specifications for the system included an ozone gas concentration of 200 ppm or more, relative humidity of 80% or more, and a treatment time that is determined by the size of the area, the inherent bioburden and the obstructions contained within the area. These systems have been employed in many industry settings and are now being considered as a possible alternative for GMP operations.

用氣體處理小范圍或大規(guī)模操作可選的另一種方式是使用臭氧。臭氧是通過氧氣加高電壓制成。該系統(tǒng)使用了高濃度的臭氧氣體,集成一個氣體發(fā)生器向待消毒區(qū)域內(nèi)釋放臭氧。該系統(tǒng)的設(shè)計規(guī)范通常為臭氧濃度200ppm或更高(注釋:臭氧1ppm≈2mg/m3, 200ppm≈400mg/m3),相對濕度80%或更高,處理時間取決于區(qū)域的大小,自身的生物負(fù)載和區(qū)域內(nèi)的障礙物情況。這個系統(tǒng)已經(jīng)在多個產(chǎn)業(yè)環(huán)境內(nèi)使用,并且現(xiàn)在正在被考慮作為GMP操作中可能的備選。

Whenever chemical agents are used for large-scale gassing or fogging of clean rooms, safety concerns must be addressed. All of the agents discussed can result in injury or death of personnel if proper precautions are not taken to ensure the containment of the chemical agent to the intended areas.

每當(dāng)化學(xué)劑用于大規(guī)模氣體處理或霧化處理潔凈室時,必須考慮安全性。如果未采用正確的防范措施來保證化學(xué)消毒劑被遏制在擬處理區(qū)域范圍內(nèi),那么所討論的所有消毒劑都能夠?qū)е氯藛T的傷害或死亡。

For many of the agents discussed, residues that are left behind on product-contact surfaces are also a significant concern and must be evaluated.

對于所討論的大部分消毒劑而言,在與產(chǎn)品接觸表面的殘留物也是一個重要問題,必須評估。

Although these methods of decontamination are effective, they should not be used to replace a routine program for cleaning and disinfecting the clean room areas. If they are used as the standard practice, they should be validated to demonstrate their ability to achieve an appropriate level of bioburden reduction. This should be performed taking into consideration the material of construction present in the clean room areas.

盡管這些消毒方法是有效的,然而它們不能取代清潔和消毒潔凈室區(qū)域的例行程序。如果它們作為標(biāo)準(zhǔn)實(shí)踐使用,那么應(yīng)當(dāng)對其進(jìn)行驗證以證明它們能夠使生物負(fù)載降低適當(dāng)水平。實(shí)施這個驗證時應(yīng)當(dāng)將潔凈區(qū)內(nèi)的構(gòu)造材質(zhì)考慮在內(nèi)。

It is also important to consider the source of these organisms, for gassing will only remove what is present and may leave behind moisture, allowing for further proliferation if the causative agents have not been removed from the area.

同樣重要的還有考慮這些生物體的來源,因為氣體處理只能除去存在的生物體,并會留下濕氣,如果病原體沒有從區(qū)域中除去,會使得其進(jìn)一步增殖。

參考文獻(xiàn)

臭氧氣體濃度200 ppm或更高,相對濕度為80%或更高以及滅菌時間為120分鐘。通過放置通風(fēng)裝置以確保均勻的氣流,使臭氧氣體滅菌過程中氣流可以覆蓋整個房間。通過將臭氧氣體滅菌過程中的臭氧氣體濃度乘以滅菌時間得出的濃度目標(biāo)值(mg / m(3)(= ppm)×min)等于或大于24×10(3)(ppm·min)。使用生物指示劑(BI)確認(rèn)潔凈室中的消毒結(jié)果,在所有測量點(diǎn)都獲得了陰性結(jié)果,這表明在引入臭氧氣體消毒系統(tǒng)的實(shí)際工廠中有效地進(jìn)行了消毒。

——Biocontrol Sci. 2013;18(1):9-20. doi: 10.4265/bio.18.9.Confirmation of the sterilization effect using a high concentration of ozone gas for the bio-clean room,Takuji Iwamura 1, Katsunori Nagano, Toshihiro Nogami, Noritomo Matsuki, Noriyoshi Kosaka, Hideharu Shintani, Miyoshi Katoh

臭氧消毒后殘留濃度

GB/T18883《室內(nèi)空氣質(zhì)量標(biāo)準(zhǔn)》:0.16mg/m3